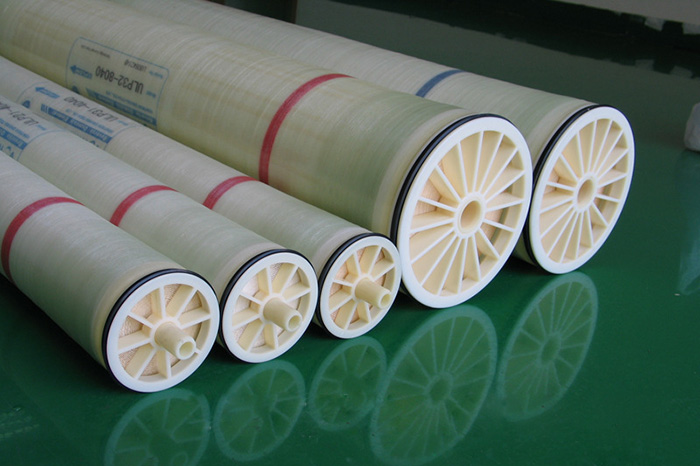

Water treatment Equipment > Reverse osmosis membrane zl-fs001

reverse osmosis membrane

Equipment parameters:

Name: reverse osmosis membrane

Model: zl - fst001

Applicable objects: water

USES: water filter

Thickness: 0.1 (mm)

Scope: pure water filter

Filtering method: reverse osmosis

Performance: acid, alkali resistant, waterproof

Operating pressure: 11 (MPa)

Working temperature: 30 (℃)

Filtration precision: 0.01 nm

Intercept molecular weight: (3700)

Aperture: 0.001 (microns)

Flux: 800-800 (L/H)

Longitudinal strength: 6 (MPa)

Specification: 8"

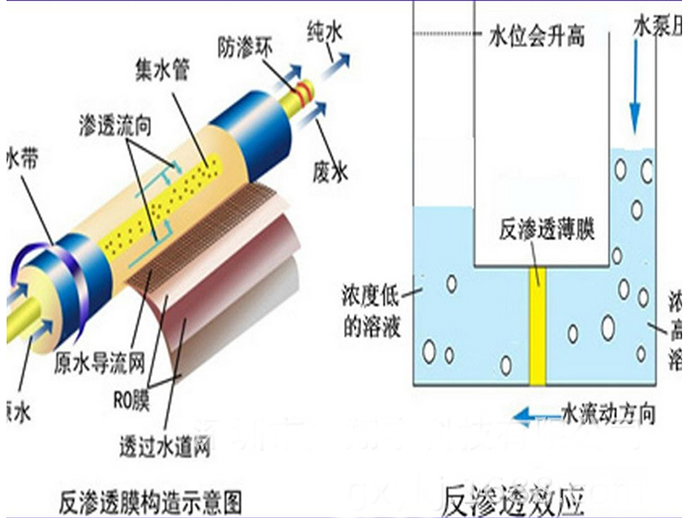

A reverse osmosis membrane Is the core of the realization of reverse osmosis element, is a kind of simulation have certain characteristics of biological membrane made from artificial semi-permeable membrane.Commonly used polymer materials.Such as cellulose acetate membrane, aromatic hydrazide film, aromatic polyamide film.Surface pores between 0.5 ~ 10 nm in diameter, and the size of the permeability and the chemical structure of the membrane itself.Some polymer materials good repellency of salt, and water through the speed is not good.Some polymer chemical structure with more hydrophilic group, and water through the speed is relatively fast.So a satisfactory reverse osmosis membrane should have appropriate osmotic quantity or desalination rate.

Reverse osmosis membrane should have the following characteristics:

1.Should have high efficiency under high velocity desalting rate;

2.With high mechanical strength and service life;

3.Can operate at a lower pressure function;

4.Ability is affected by chemical or biochemical effect;

5.Affected by factors such as pH, temperature, smaller;

6.The membrane easy raw material source, processing is simple, low cost.

7.The structure of the reverse osmosis membrane, there are two categories, homogeneous and asymmetric membranes.Currently used mainly for cellulose acetate membrane materials and aromatic polyamide class.Its components are hollow fiber type, volume type, plate and frame type and tube type.Can be used for chemical unit operations, such as separation, enrichment and purification of is mainly used in the preparation of pure water and water treatment industries.

reverse osmosis membrane

Principle:Reverse osmosis, also known as reverse osmosis, a differential pressure as the driving force, isolated from the solution of solvent membrane separation operation.Of membrane material liquid pressure, when pressure exceeds its osmotic pressure, solvent will reverse the direction of natural penetration for reverse osmosis.To get through on the low voltage side of the membrane solvent, namely penetrating fluid;High side concentrated solution, that is, concentrate.If use seawater reverse osmosis treatment, on the low voltage side of the membrane to get fresh water, brine in the high side.

Reverse osmosis, the penetration rate of the flow energy of the solvent N: N = Kh (delta p - delta PI) type of Kh for hydraulic permeability coefficient, it increases with temperature increase slightly;The delta p for the static pressure difference on both sides of the membrane;The delta PI for membrane solution of osmotic pressure difference on both sides.Dilute solution of osmotic pressure PI for: PI = iCRT type I to solute molecules in the ionization ion generated number;C is the molar concentration of the solute;As the molar gas constant R;T for the absolute temperature.

Reverse osmosis is often use asymmetric membranes and composite membranes.Used in the reverse osmosis equipment, mainly for hollow fiber type or volume type membrane separation equipment.

Reverse osmosis membrane can intercept the water of all kinds of inorganic ions, colloidal substance and macromolecule solute, thus to obtain the net is made of water.Can also be used for the preconcentration of macromolecular organic solution.The reverse osmosis process is simple, low energy consumption, get rapid development in recent 20 years.Has large scale (see brine) desalination of seawater and brine, boiler water softening and wastewater treatment, and combined with ion exchange high pure water, its application range is expanding, already used in dairy, juice concentrate and the separation and enrichment of biochemical and biological agents.

Reverse osmosis membrane cutting principle

2. Reverse osmosis membrane filtration precision:

Reverse osmosis membrane can intercept is greater than 0.0001 micron material, is one of the most delicate membrane separation products, it can effectively intercept all dissolved salts and organic molecular weight greater than 100, while at the same time allowing water molecules to pass.

3. Reverse osmosis membrane type:

There are often customers asked in need to consider what we choose to reverse osmosis RO membrane performance metrics.Usually divided into three: desalination rate, water rate, recovery rate.

(1). The RO reverse osmosis membrane desalination rate and rate of salt.

RO reverse osmosis membrane element desalination rate have been identified in its manufacturing forming, desalination rate depends on the RO RO membrane element surface density of ultra-thin layer, layer dense desalting rate is higher and higher, at the same time, the lower the water rate.Reverse osmosis membrane desalting rate of different material is mainly determined by the material structure and molecular weight, the high ion and complex monovalent ion desalting rate can be more than 99%, the monovalent ions such as sodium, potassium, and chloride ion desalting rate is slightly lower, but also can be more than 98% (the longer the use time of reverse osmosis membrane, chemical cleaning, the more the lower the reverse osmosis membrane desalting rate) on organic matter removal rate of the molecular weight greater than 100 can also lead to 98%, but the low molecular weight organic matter removal rate of less than 100.

Reverse osmosis membrane desalination rate and through salt rate calculation method:

RO membrane salt transmittance =RO membrane water production concentration and inlet concentration by .

RO membrane desalination ratio =(1-RO membrane water salinity/water salinity) x.

The RO membrane through salt rate = , desalination rate.

(2). The RO reverse osmosis membrane water rate and infiltration flow rate.

RO membrane water rate - refers to the capacity of water of reverse osmosis system, through the RO membrane water per unit of time, usually with tons/hour or gallons per day.

RO membrane permeate flow rate, and it said one of the important indices for reverse osmosis membrane element water rate.Refers to the unit through the liquid flow rate on membrane area, usually expressed in gallons per square foot (GFD) every day.High osmotic flow rate will lead to accelerated perpendicular to the RO membrane on the surface of the water flow, aggravate membrane fouling.

(3). The recovery rate of RO reverse osmosis membrane.

RO membrane recovery - refers to the reverse osmosis membrane system of feedwater converted to produce water or through the percentage of the fluid.Based on the pretreatment in reverse osmosis system of feed water quality and water requirements.The recovery rate of RO membrane system in design have been confirmed.

1). The recovery rate of RO membrane = (RO membrane produced water flow and water flow) x .

2).Reverse osmosis (nf), the recovery rate of membrane module, salt transmittance, desalination rate computation formula is as follows:

The recovery rate of reverse osmosis membrane module = water rate/RO membrane components into the water by .

The salt content of the reverse osmosis membrane components through concentration ratio = RO membrane module production water/water concentration by .

Related products