Water treatment Equipment > Zl - pzs001 bottled water production line

Bottled water production line

Equipment basic configuration:

Name: bottled water production line

Model: zl - pzs001

Voltage: 380 (V)

Power: 50 (kw)

The damage: 0.000001 (%)

Filling capacity: (2000-10000 bottles per hour)

Product use: mineral water production line

Packing: packed in wooden cases

Scope: tea restaurant equipment, drinks store equipment, brewery equipment, fruit and vegetable processing equipment, frozen food factory equipment

This company produces the automatic bottle blowing machine, semi-automatic bottle blowing machine, infrared rotating oven, hot filling bottle blowing machine, heat-resistant bottle bottle crystallization machine, etc. Series of products, with a high degree of automation, stable performance, beautiful wait for a characteristic, both at home and abroad by the user's consistent high praise.The machinery is mineral water, beverage, pharmaceutical, oil, chemicals, reagents and other manufacturers the ideal choice.

Product features:

This machine structure is compact, perfect control system, convenient operation, high degree of automation;

Transform bottle shape need to replace the screw cap part of the star wheel, arc guide plate can be realized;

And material contact parts are made of high quality stainless steel manufacturing, process dead Angle, easy to clean;

Adopting high speed filling valve, liquid level accurately without fluid loss, ensure filling process requirement;

Cover sealing device adopts magnetic constant torque, to ensure the quality of blocks, and will not damage the cap;

By high cap system, has the perfect automatic control and protection devices;

A perfect overload protection device, can effectively protect the safety of equipment and operators;

Control system with production speed control, the lack of detection, card bottle automatic stop counting and yield, and other functions;

Main electric components and pneumatic components adopt world famous brand products.

The operation USES the advanced touch screen control, which can realize the man-machine dialogue operation

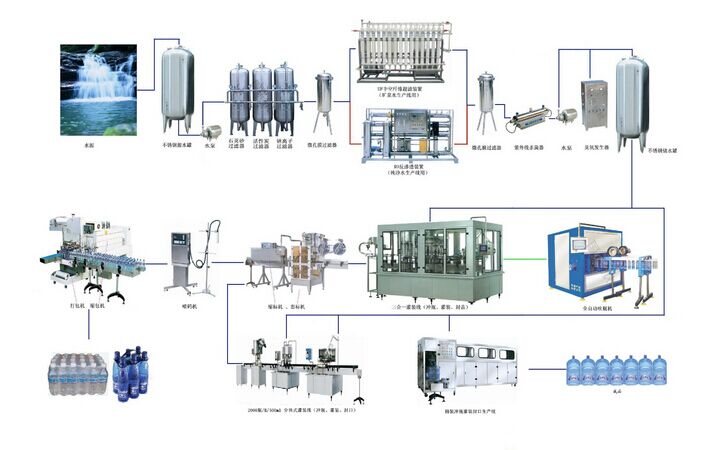

A full set of production line flow chart:

Remark:

The final size of the equipment model according to certain products will have corresponding change.

Other specifications can handle, but relevant equipment would be required to increase corresponding replacement parts or different design.Pending data still need to provide to the seller.

Related technical parameters and the design of the machine will be confirmed after got all the information and sample evaluation

Related products