Water treatment Equipment > Zl - cjs001 pure water equipment

Reverse osmosis pure water treatment equipment

Equipment basic configuration:

Name:pure water equipment

Type:zl - cjs001

Inlet diameter: 32 (mm)

Water rate: 1 ton

Specification: 3200 x2300

Job stress: 15 (psi)

Summary of technology.

Reverse osmosis water treatment is a kind of with the aid of choice through (through) the skill of membrane to pressure as the driving force of membrane separation technology, when system and the pressure is greater than in the aqueous solution of osmotic pressure, the water molecules through the membrane unceasingly, after producing water flows into the central tube, and then out in the end the impurities in the water, such as ion, organic matters, such as bacteria, viruses, interception on the inlet side of the membrane, and then in the thick water outflow water end, so as to achieve separation and purification.

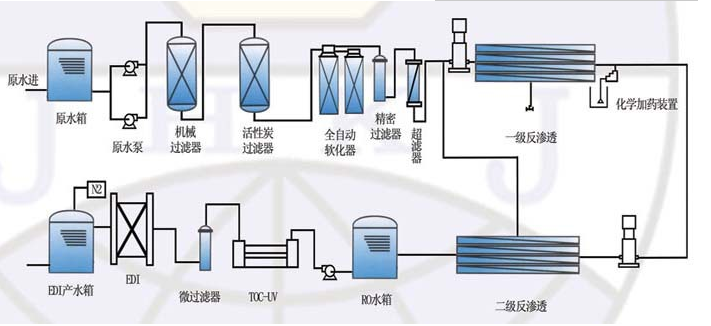

Process description:

1. The original water tank

Storage of raw water to precipitate the large sediment precipitation granules and other substances in the water.Buffer at the same time the original pipe water pressure instability in the impact of the water treatment system.(such as water pressure caused by too low or too high pressure sensing response).

2. The original water pump

The constant pressure of water supply system, stable water supply.

3. Many medium filter

Several times with filter layer filter, the main purpose is to remove sediment, rust, colloid substances contained in the raw water, suspended solids and other particles in more than 20 um material, can choose manual control or automatic valve controller reverse flushing, is washed and a series of operations.The quality of the water production equipment, prolong the service life of equipment.

4. The activated carbon filter

System USES nut shell activated carbon filter, activated carbon adsorption electrolyte ions, not only can also ion exchange adsorption can be performed.By activated carbon adsorption also can make the potassium permanganate oxygen consumption (COD) consists of 15 mg/L (O2) reduced to 2 ~ 7 mg/L (O2), in addition, due to surface adsorption have been copied adsorption concentration increases, and therefore also play a catalytic role, removal of the pigment in the water, bad breath, a large number of biochemical organic matter, reduce the residual chlorine water and pesticide pollution and the water to remove the three halide (THM) and other pollutants.Can choose manual valve control or automatic controller reverse flushing, is washed and a series of operations.The quality of the water production equipment, prolong the service life of equipment.At the same time, the device has self maintenance system, operation cost is low.

5. Ion softening system/dosing system

R/O device in order to dissolve the solid shape content enrichment of emissions and the use of fresh water, to prevent the thick water side especially RO device last membrane module thick water side of CaCO3, MgCO3, MgSO4, CaSO4, BaSO4, SrSO4, SiSO4 concentration is greater than the equilibrium solubility constant deposition and crystallization precipitation, damage the membrane of the original features, before entering the reverse osmosis membrane module, you should use ion softening device or put in the right amount of scale inhibitors prevent carbonate, SiO2, sulfate crystal precipitation.

Precision filter 6.

Using precision filter into the water the pesticide residue suspended solids, breed and colloidal substances such as grain materials from, after making the RO system

Equipment operation safer, more reliable.Filter for 5 um melt-blown filter, aim to prevent the superior filtration unit, missing is greater than 5 um to remove impurities.Prevent damage of into the reverse osmosis unit membrane surface, and damage the desalination performance of membrane.

7. Reverse osmosis system

Reverse osmosis device is with enough pressure to make the solution of the solvent (usually water) through the reverse osmosis membrane (or a semipermeable membrane) and separated, because of the process and the natural infiltration in the opposite direction, therefore is called reverse osmosis.Reverse osmosis method can adapt to all kinds of salt content of raw water, especially in the high salinity water treatment engineering, can get very good technical and economic benefits.Reverse osmosis desalination rate, high recovery rate, stable operation, cover an area of an area small, easy to operate, at the same time of desalination, reverse osmosis equipment will also be most bacteria, colloid and large molecular weight organic matter removal.

8. Ozone sterilizer (optional)

Kill bacteria produced by secondary pollution thoroughly to ensure that the finished water health indicators.

Related products