Water treatment Equipment > Zl-nsy001 urea liquid purified water of a complete set of equipment

Purified water for urea solution of a complete set of equipment

Equipment parameters:

Name: purified water for urea solution of a complete set of equipment

Model: zl-nsy001

Operating pressure: 15.5 (Mpa)

Water resistivity: 16 ohms/cm

Water: 1.0 m3/H

Dimension: 200 * 100 (cm)

Voltage: 280 (V)

Water, ultrapure water

Power: 12250 (w)

Electrical conductivity: 0.0625 us/cm

The desalination rate: 99.8 (%)

Single output: 1.0 m3/h)

Summary:

Urea is specially for diesel engine exhaust gas purification reductant.It is a tasteless non-toxic solution, special storage container stored in a diesel car.When the waste gas from engine exhaust, it will reach the SCR catalytic converter with exhaust gas, and then convert nitrogen into harmless nitrogen and water, thereby significantly reducing emissions.Urea abroad generally called Adblue or DEF, equipped with Adblue diesel has a separate container to store, currently SCR (selective catalytic reduction technology) technology into diesel engine Ⅳ standards preferred.The domestic engine manufacturers started using SCR technology to meet environmental requirements.

Urea (urea, automotive car car environmental urea) refers to the urea concentration is 32.5% and the solvent is urea aqueous solution of ultrapure water, raw materials for urea crystal and ultrapure water, the key point is that the purity of raw materials.Its scientific name is diesel exhaust treatment fluid, used in diesel engines, is a kind of SCR technology must be used in consumables, used to reduce nox in diesel exhaust pollution of the liquid, the composition of 32.5% urea and 67.5% of high purity deionized water.

Heavy trucks, buses and other diesel vehicles to achieve the four emissions standards, be about to choose a suitable SCR on tail gas processing system, and the system must use urea solution to deal with nox in the exhaust gas.Therefore, automotive urea solution became heavy trucks and buses to reach the discharge standard of essential products.

The current domestic existing diesel gb GB19147 sulphur 350 PPM or less - 2009 requirements, technical requirements and ECR - DOC oil sulfur content in 10 parts per million, therefore temporarily have no promotion condition in China.SCR is 350 PPM sulfur resistant oil, thus promoting technology base.Four engine fuel economy due to the kingdom of the SCR technology is better than EGR, the engine changes little, low requirements for fuel oil and engine oil, has advantage in the technology upgrading continuity, SCR, good durability and there is no catalysts congestion risk, so the SCR technology is the most suitable for the heavy duty diesel emission reduction technology for China's national conditions.

purified water for urea solution of a complete set of equipment

Automotive urea demands for raw material purity is higher than general industrial use, mainly from industrial purification of urea,The main principle ofAs follows.

1.In the temperature 70-75 ℃, the hydrolysis of urea occurs in aqueous solution.

2.When the temperature below 30 ℃, urea crystallization from aqueous solution.

3.Every hydrolyzed crystallization, its purity will be greatly increased, and generally using industrial grade urea hydrolysis crystallization time, can meet the requirements of automotive urea standard, its output ratio of 1.5:1.

Formula of equipment:

1.The purification of urea

As the vehicle urea to demand higher purity, generally USES urea urea) (impurity content is lower than the agricultural industry for purification, in 70-75 ℃ when the urea hydrolysis occurred in aqueous solution, below 30 ℃ urea crystallization from aqueous solution, hydrolysis of crystallization can greatly improve the purity of urea at a time, a general industrial level of urea hydrolysis crystallization can reach the standard for urea.

2.Water treatment

Automotive urea on strict control of impurities, ordinary tap water or use a deep groundwater to filter into pure water by reverse osmosis equipment, as a vehicle of urea solution preparation.

3.The configuration for urea liquid

Vehicle of the urea content in urea solution is commonly 31.8% ~ 33.2%, urea production car after for the purification of the final step is to clean water and urea mixed dissolve, and then to filling.

Urea solution purified water equipment

Production process:

Urea (urea, automotive car car environmental urea) scientific name is diesel exhaust treatment fluid.Used in diesel engines.It is a kind of SCR technology must be used in consumables, used to reduce nox in diesel exhaust pollution of the liquid.The composition of 32.5% urea and 67.5% of high purity deionized water.

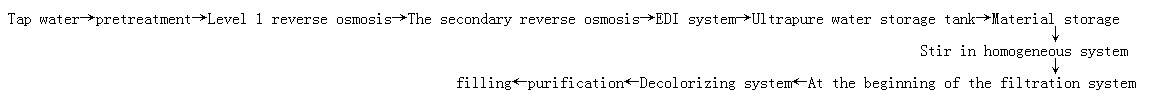

1.Water system process

Raw water to the original water tank, pump to the sand filter, activated carbon filter - scale inhibitor dosing - 5 mu precision filters - > level high-pressure pump - level of membrane treatment system - level RO water tank to the secondary high pressure pump, the secondary membrane processing system to secondary RO - RO water tank, EDI into the water pump to EDI device, pure water to pure water pump, mixing tank

2.The urea production process

System description:

At the beginning of the production line by premixed system, filtration system, homogeneous systems, decolorization and purification system, etc, the operation mode for urea production technology is advanced and mature vehicle, has entered a stage of large-scale industrial production.This kind of production mode and concept, in sinopec, can LanSu and yuchai, hubei wei automobile exhaust and other companies have production operation;

(1).At the beginning of filtering and decolorizing system: removal of suspended solids in urea and other impurities floating, guarantee the process after the unaffected.Decolorizing system is made of high quality activated carbon adsorption bleaching and remove other organic impurities in urea, urea solution more clear.

(2).Fine filtration system: prevent decolorizing activated carbon particles in the system to enter after processing, affect the quality of the product after.

(3).Purification system: adopting multi-stage purification tower, remove all kinds of ions, biuret urea solution, the impurities such as phosphoric acid root, ensure that the product conforms to the Chinese automotive engineering society specification SAE - China J2901-2013 "technical specification for urea solution" standard requirements.

(4). Microfiltration system: interception process piping, storage tank, power equipment, may produce some of the residual impurities are not visible to the naked eye, ensure the quality of the finished product is stable and reliable.

(5). Reduction regeneration system: purification tower in the process step by step in the process of failure, reaches a certain cycle reduction regeneration process, process must be six to eight hours.After the reduction treatment on purification tower, can fully meet the requirements of the original production technology.Each regeneration cycle process will produce 2 tons of wastewater, the wastewater contains no other heavy metals, mainly PH value does not conform to the requirements.After adjusting and can achieve environmental emissions standards.

Product quality and design standards:For urea production line Compliance with automotive engineering society of China specification SAE - China J2901-2013 standard for automotive urea solution specification requirements.

Urea solution purified water equipment

Metal ion poisoning because of SCR catalyst carrier easily happened to lose their catalytic effect, so the vehicle urea solution must use the electronic ultrapure water industry level.Automotive urea solution will start freezing under 11 ℃, in actual use will completely frozen in - 20 ℃.Now technology is by adding modified agent reduce the freezing point, additional heating device to prevent solution set.

[!--temp.fenxiang--]Related products